Today is a '92 Chevy K2500 6.5 diesel with a complaint of a TPS fault code that won't go away. The TPS (throttle position sensor) has been replaced but the code remains.

Ideally what I would like to see is the code number and scan tool data that would show me what the engine computer is reading as TPS voltage. I do have scan tools that read these older GM systems but when I tried the OTC Genisys with the Pathfinder attachment there was no 6.5 diesel under engine options. Ok, I have an AutoXray tool. No communication. OTC Monitor 4000 Enhanced, remember those? Uh.. no. I have attachments for the Solus Pro for GM but maybe I should just read the codes as this scan attempt is turning into a time consumer. Now if you want to read the codes on one of these using primitive tools, you can. You need a working SES (service engine soon) light so turn the key and see that it does come on.

Turn the key off. Find your diagnostic connector under the dash. (Not a good shot.)

I'm gonna share a tip here that you might need to know some day, or maybe never, but it's a good tip anyway. If you look closely at this diagnostic connector you can see there are small "ears" sticking out from each corner at the bottom making it wider at the bottom than at the top. Those ears are the bottom of the connector no matter how it is positioned in the car. If you are working on a car and find that connector turned upside down from this picture, or turned sideways in either direction it doesn't matter. That widest part is still the bottom of the connector. The reason that is important is that to trigger the SES light to flash trouble codes you have to jumper those two terminals on the upper right of the connector. You can't tell where the upper right is if you don't know where the bottom is. You can use a wire or I'm going to use a paper clip. Jumper the two connectors at the upper right.

Once you get the jumper in place, get in a position to turn on the key and watch the SES light. The light should begin flashing when you turn the key to the on position. Don't start the truck. Just turn on the key and watch the flashes. You may need to make a note of the codes if there are several. On this truck the light should flash a 12 initially. That is one long flash, pause, two short flashes. The code will be repeated three times. 12, 12, 12 long pause and then next code if any. In this case the only code output other than 12 was 22. Turn your key back to off and remove your jumper.

Now the short description for a 22 is probably going to be something like throttle position sensor voltage low. There is a school of thought that you'll come across that believes a sensor code means you need a sensor. It's wrong. What the code 22 is saying here is that the engine computer isn't seeing a voltage signal from the TPS. Sure that could be a bad sensor but it could also be many other things and no diagnostics have been done by reading a code. It's the first step, not the journey.

The next step is to inspect. The sensor is obviously new and the connector looks ok.

This sensor has three wires. It needs a ground on the black wire, a reference voltage on the gray wire, and the blue wire carries the voltage signal to the engine computer. Since the code is saying there is no voltage on the blue wire, I'll start with that. Connect a meter to measure voltage on the blue wire and turn on the key. The code isn't misleading at all. There is low voltage on the blue wire.

What I need to know next is if I have a reference voltage and ground going to the sensor. If the ground and reference circuits are good then I can connect the meter between the two wires and see reference voltage when I turn on the key. Disconnect the TPS and connect the meter leads to the black and gray wires on the engine side of the harness, turn the key on.

The five volt reference voltage is there. Since I'm measuring between the sensor ground and reference wires at the connector then I know the sensor is getting what it needs from the engine harness. Let's go back to the blue wire. The blue is the actual signal from the sensor to the engine computer. I measured before and saw no voltage on the signal wire. This time I'll measure the voltage on the wire while accelerating by just manually pushing the throttle shaft open.

As I open the throttle, the sensor signal voltage rises from 0 to 4 volts. The sensor does work. So why do I have a code 22? A code 22 will set when the TPS signal voltage drops below .06 volts. It does that each time the throttle is closed so that sets the code. At closed throttle the sensor reading should be .5 volts. The sensor is slotted and is adjustable. This could be a matter of the sensor not being adjusted when installed. I'm going to monitor the voltage signal, loosen the mounting screws and see if I can get .5 volts at closed throttle by adjusting the sensor.

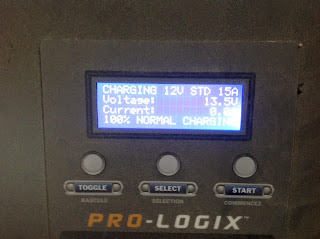

Success! What I'm going to do now is disconnect the battery to allow the code to clear from memory. Don't do this on most cars and only for a reason on those you do. On this model that is how the codes are cleared and not with a scan tool. I'll give it a test drive and then another check of codes to see if the 22, or anything else, returns.

All good! That's the magic!

Kenneth Hayes

G&G Auto Repair