Thursday, October 11, 2007

Diagnostic Tech: '92 Ford Tempo EECIV

On the plate today is a 1992 Ford Tempo w/2.3 engine and automatic transmission. The complaint is an intermittent Service Engine Soon light on and a high idle speed at that time. This system does store trouble codes in memory but should only turn the SES light while a code setting condition is present. In this case it just seemed to me that a test drive to verify the complaint was in order.

Initially the car ran fine. No light came on and even though I was driving in stop and go traffic there were no idle speed problems. I decided to return to the shop and just run the EECIV self-tests. When I pulled into the driveway the SES light came on. The idle speed was fine until I stopped and put the car's shifter into park position. The idle speed went to around 2000 rpm and stayed there for about three seconds before slowing back to normal. I had just verified the complaint. Time for the EECIV checks.

The car's test connector is at the left shock tower, near the battery. Technically there are two connectors. One is a single wire called the self-test input connector.

I'm going to mention that there are alternatives to retrieving codes. You don't have to use a scan tool. That being said, you will find the scan tool method more reliable with less chance of misreading a code number or accidentally clearing memory codes.

It is important to understand EECIV self-tests before using them to find a problem. Ford has the car's computer run specific tests and report back areas that failed the tests. The failures are reported as trouble codes. Running the tests improperly can give you misleading results.

A quick warmup cycle for the engine and I'll get started.

After connecting the scan tool to the test connector and entering the car data I want to start with "Quick Tests" and the Key On Engine Off tests. If a sensor fails the KOEO test then it should be repaired. You'll need a "Pass" or a no fault found condition in the KOEO self-test before any KOER (Key On Engine Running) tests can be reliably done.

The KOEO running test results are called "On Demand" codes. In this case I get a Pass code 111 which means no problems were found. After the On Demand codes are displayed the Keep Alive continuous memory codes will be displayed. The Keep Alive, or continuous codes are codes from the car's computer memory. Codes that have set in the past. This car has a 332 in memory. A 332 indicates insufficient EGR flow. I don't think a problem with the exhaust gas recirculation system it going to be related to the high idle or even the SES on at that time. An EGR not flowing should not cause the idle speed to be higher and since the EGR is not supposed to be flowing at idle anyway I don't think it would turn the light on at that time. I'm going to move on to the KOER tests because that test should be done before getting too involved with Continuous codes. The KOER test will reveal any sensor failures that happen during the test.

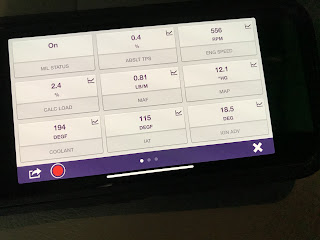

The KOER test codes indicate a 332 again. This time I know the EGR failed a test in real time and currently has a problem. Again though, I don't think it is related to the idle speed problem. Two more codes do indicate a problem with idle speed control, a 412 and 411. These codes indicate the car's computer not being able to control the idle speed. These codes do not store to memory so without running KOER tests we would not see them. If you think that was a lot of trouble to find that something is wrong with the idle speed you have a point. What was learned though is that the several sensors that contribute to the computer choosing an appropriate idle speed do pass self-tests. That means I should start by concentrating my efforts in testing the computer's ability to control the idle speed. In other words, I've learned that the inputs to the computer are likely to be fine but there is a problem with the idle control output circuit.

It's a good idea, I think, at this point to check the base idle and minimum air adjustment. Before any throttle adjustments are made I want to be sure I have a clean throttle plate. I'll remove the air intake hose, the MAF and the air cleaner cover as a unit. The throttle plate actually doesn't look too bad. It's pretty clean on the air cleaner side. The air filter looks good and the air cleaner housing was properly fastened.

When I open the throttle fully and look past the plate I can see major carbon buildup. I can even see why the EGR flow is low. The EGR passages are just behind the throttle body and fully plugged with carbon. The best thing to do here is remove the throttle body, remove the EGR valve and do some cleaning.

While we are in the neighborhood, this is a good time to remove the Idle Air Control (or Air Bypass Valve) and clean that passage as well. The engine computer uses this valve to control the amount of air that bypasses the throttle plate. The amount of air allowed controls the engine idle speed.

Once everything is clean and reinstalled it is a good idea to clean the MAF sensor or at least see if it needs cleaning. Two tamper proof screws hold the MAF to the MAF housing. A torx T20H will fit the screw heads. Carefully remove the MAF from the housing. With a magnifying glass and a good light you can look for dirt on the two tiny wires at the bottom of the sensor. If you see dirt, carefully clean it. These days there are spray MAF cleaners on the market. That wasn't always the case so I still use the same Berryman Spray Carb Cleaner that I always did. For stubborn spots I use a Q-tip as well.

This particular MAF looked pretty clean so after reinstalling it I let the engine warm up again. I know that I now have a clean throttle, a clean MAF, a clean IAC and a clean EGR passage but what I don't know is if I've fixed any of the complaints. It's time to run the KOER test again.

After getting the same results with the KOER self-test as before all this work, I decided to see just what was happening at the Idle Air Control as far as the computer control was concerned. The voltage at the IAC signal wire should roughly match the position being commanded by the computer. A command to open the valve 34% would have 3.4 volts. As a load is placed on the engine the command would increase, so a voltmeter could be used to check the command to see if the computer is trying to slow the idle speed during the high idle problem. Another method would be to disconnect the IAC wire connector from the valve and see if the engine slows. You see, the valve is spring loaded to return to minimum air position without a voltage command to the contrary. In fact, it is by disconnecting the IAC and adjusting the throttle position stop screw that minimum idle air is adjusted. All I have to do is wait for the high idle problem to appear. After a few minutes of running time the engine idle speed begins to race. When I disconnect the Idle Air Control the rpms do not change. The IAC valve is bad. I suspect a vacuum leak within the valve is the problem.

After replacing the IAC valve I now have no more racing idle and no more idle control related fault codes. One thing very good about the EECIV testing method is that I can rerun the test after a repair to verify the problem is fixed. The idle problem is fixed! BUT the EGR problem remains. I still have a 332 fault code in the KOER test.

During the KOER self-test the ECM will open the EGR vacuum regulator solenoid very briefly. This allows manifold vacuum to pass through the solenoid to the EGR valve. The vacuum should open the EGR valve. The pressure in the exhaust tube that runs to the EGR valve is measured by the PFE sensor. If the ECM has commanded the EGR solenoid to open yet does not see the PFE sensor voltage indicate a pressure change the ECM will assume the EGR is not working and will set the 332 fault code.

For testing purposes I like to use a length of vacuum hose and bypass the solenoid, feeding the vacuum directly to the EGR valve with the engine running at idle. If the engine nearly stalls then the valve is passing plenty of exhaust flow.

I started to do that here but noticed that the hose that feeds pressure from the EGR exhaust tube to the PFE sensor was broken. With a broken hose the PFE sensor would not be able to monitor the exhaust tube pressure change and would indeed set the 332 code. A replacement hose and another KOER test and this time the repairs were done! A complete system pass. No more light, no more high idle, no more codes!

Kenny@GGAuto.repair