A lot of people don't realize just how long onboard diagnostics, trouble codes and scan tools have been part of car repair. It isn't new. Now at first, scan data wasn't an option. You had no access to it and since trouble codes could be read by triggering a check engine light you also didn't necessarily need a scan tool for reading codes either. As things progressed it was General Motors that was the friendliest to a tech trying to diagnose system problems and sort out codes. They gave us the golden gifts of scan data and code set conditions very early on. Chrysler came around a bit later and Ford finally started giving up scan data as well. The Asian cars were last to see the benefits. I remember a Nissan spokesperson saying they didn't need scan tool data because their mechanics knew how the cars worked. Well in those days all the computer was doing was reading sensor voltages and reacting to those inputs. You could monitor inputs yourself with access to the wiring and a meter. Aggravating but it could be done. Anyone remember breakout boxes? What the Nissan guy missed though was that you were seeing something with scan data that you could not see with a meter and a voltage measurement. The meter would show you what the sensor was doing, what the signal looked like. But what the scan data was showing you was how the computer was interpreting that signal and sometimes it wasn't seeing the signal correctly. If that coolant temp signal was correct and normal voltage-wise and that was all you had you'd be missing the fact that on the scan data the computer was reading -40F on a 198F coolant temp. Scan data, never take it for granted. A look inside the electronic "brain". Related closely to that was supplying us "techs" with the actual conditions that cause a code to set. A code doesn't tell you what is wrong, just tells you something is not right and it may involve a particular system. Basically a test failed. The short description doesn't tell you what is wrong, just what the test may have been about. But given the information about how the test is performed and what actually must occur to fail and you got something to latch on to and use to find the problem. The scan data and the code test conditions are golden things to have access to.

Now I started out to tell you this has been around for a long time now. Let me show you my first actual scan tool. The tif 1500. Printed scan data out on a piece of paper like an adding machine printer. Which made "LIVE" data actually several seconds delayed. Used IBM punch cards to determine the car you were scanning.

BTW, the tif 1500 was followed up by the more highly advance tif 1600. Actually these were good learning tools back then and you got the neat little printout receipts to attach to the repair order.

The first more recognizable as a scan tool piece of history I got was called the OTC 4000 Turnkey System. It was a OTC 4000 scan tool, an external data recorder, a pc type monitor and a pc type keyboard and a small external printer all connected together and stored in a metal cabinet that I placed on an old SUN machine roll cabinet (having removed the actual SUN machine that had stopped working way before that). The OTC used cartridges placed into the tool for various cars and systems. Here are my earliest cartridges for the tool.

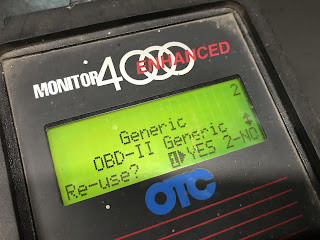

Part of the OTC system was to include repair manuals with detailed information concerning systems, wiring, diagnostic procedures, etc. Each software update brought some new manuals and service bulletins. It was a good time to be alive. Eventually the hardware, OTC 4000 had to be upgraded but all the previous cartridges and test leads would still work with the amazing new OTC 4000E. The original 4000 was a trade-in and time marched on right up to when OBDII became a thing. Let me point out something here, the OTC 4000E was a much improved tool over the 4000 but it would not read the new OBDII protocol systems. Trade-in time again. The OTC 4000 Enhanced, the '98 software and the new test lead (System Smart Cable) along with System Smart keys and you were good to go. The OTC 4000, the 4000E and the 4000 Enhanced are three different (but similar) tools. I always feel I have to stress that because of the three the Enhanced it the only one that will read OBDII systems and to this day if you look at the tools on ebay you will see the names freely interchanged between the three tools.

The Enhanced actually says Enhanced on the tool, not E. Don't be fooled.

This was my first OBDII scan tool. There is a LOT of misinformation about OBDII online. It is a protocol for monitoring and reporting problems with emission systems. That is the basic purpose. OBDII standardized the system information across car makes. It no longer mattered to my scan tool if I was looking at a Toyota or a Ford. In Global/Generic OBDII all the tool wants to see to get started is a communication protocol that it can recognize.

This OBDII connector is a J1850 VPW protocol on a 1997 Chevy Trk.

This is a connector for a 2001 F150, uses J1850 PWM. It will read that too.

Those are both older protocols. It won't read CAN protocols which I think would mean that some of the 2006 OBDII systems would probably be as late as it will be capable of. Still, I hope you found this interesting and I hope that you now know there is nothing new about scan tools, codes or diagnostics.

Thanks for reading!

Kenny@ggauto.repair